What is the difference between color steel plate and color steel sandwich plate?

I. of color steel plate

1. Color steel plate coating is a product made of cold-rolled steel plate and galvanized steel plate after surface chemical treatment, coating (roll coating) or composite organic film (PVC film, etc.), and then baking and curing. Some people also call this product "pre roll coated color steel plate" and "plastic color steel plate".

Color plate products are produced in rolls by manufacturers on continuous production lines, so they are also called color coated steel plate rolls. Color steel plate not only has high mechanical strength and easy forming performance of steel materials, but also has excellent decoration and corrosion resistance of coating materials. Color steel plate is a new type of material highly praised in the world. With the advancement of science and technology, the enhancement of environmental awareness and the improvement of people's living standards, color steel plate movable houses show more and more strong vitality and broad market prospects, and are loved by construction, household appliances, electromechanical, transportation, interior decoration, office appliances and other occupations.

2. The color steel plate movable house has the advantages of light weight, high strength, thermal insulation, beautiful use and so on. It is a combination of construction and decoration, which is convenient for construction and installation. The construction of color steel plate movable house is clean, which is widely used in large-span workshops, warehouses, office buildings, villas, roof addition, air purification rooms, cold storages, shops, kiosks and temporary houses. Light color steel sandwich panel with a weight of less than 14kg per square meter can fully reduce the structural load and reduce the structural cost of movable house.

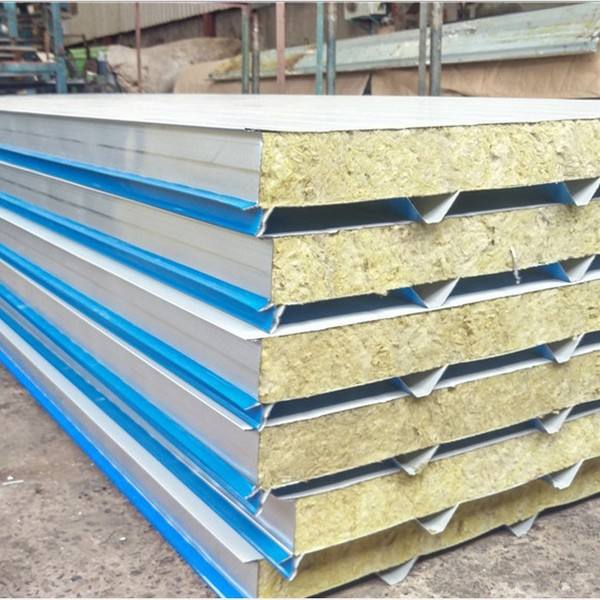

II. Color steel sandwich panel

1. The color steel sandwich panel product is composed of two-layer formed metal panel (or other data panel) and polymer thermal insulation inner core directly foamed and matured in the center of the panel. These finished sandwich panels are easy to install and lightweight. The filling system also uses closed bubble molecular structure, which can prevent the condensation of water vapor. The forming of the outer steel plate fully considers the requirements of structure and strength, and is beautiful. The inner surface is formed into a flat plate to get used to various needs. Metal panel and non-metal panel. Metal panels are easy to process and can be made into various shapes, but in some cases, non-metallic panels have functions that metal panels cannot, such as corrosion resistance, impact resistance and so on.

2. Color steel sandwich panels are widely used in large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storages, activity rooms, additional floors of buildings, clean workshops and places requiring thermal insulation and fire prevention. Color steel sandwich panel has beautiful appearance, gorgeous color and good overall function. It integrates load-bearing, thermal insulation, fire prevention and waterproof, and does not need secondary decoration. It is convenient to install, short construction cycle and good comprehensive benefits. It is a building material with wide uses and potential.

To sum up, we can conclude that the difference between color steel plate and color steel sandwich plate lies in the difference in material, production process and use. Of course, the price is slightly different. The price of color steel sandwich plate is higher than that of color steel plate.

Article source: Guangdong sandwich panel /

-

08-05

Guangdong sandwich panel: application field of color steel rock wool sandwich panel

Application field of color steel rock wool sandwich boardPublic buildings, such as waiting halls or waiting halls of airports and stations, stadiums, theaters and auditoriums, exhibition halls, conven

-

08-05

Guangdong hidden exterior wall transverse board: can polyurethane edge sealing transverse board be used for exterior wall?

The construction of external wall insulation has always been a problem worthy of attention, which is related to the quality of construction. Can polyurethane edge sealing transverse board be used for

-

08-05

Guangdong sandwich panel: how to classify sandwich panels?

1. There are six kinds of core materials: polystyrene sandwich board, namely EPS sandwich board (widely used in the market);Extruded polystyrene sandwich board, namely XPS sandwich board;Rock wool c